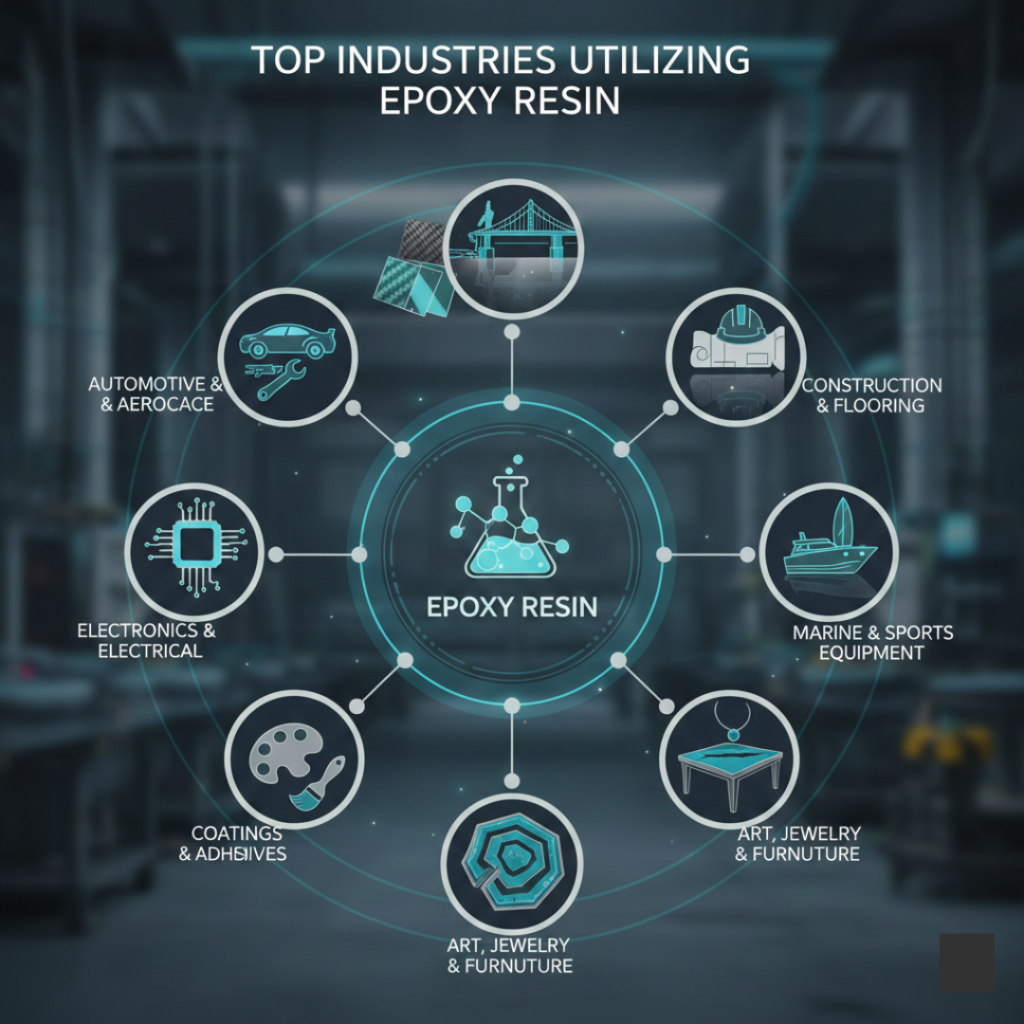

The demand for epoxy resin has grown rapidly across Pakistan due to its durability, chemical resistance, and versatility. From large-scale industrial use to creative applications, epoxy resin plays a vital role in multiple sectors. Understanding epoxy resin uses in Pakistan helps businesses, contractors, and manufacturers choose the right solutions for performance-driven projects.

In this blog, we explore the top industries using epoxy resin in Pakistan, highlighting how this material supports growth, efficiency, and long-term value.

Construction & Infrastructure Industry

The construction sector is one of the largest contributors to epoxy resin uses in Pakistan. Epoxy resin is widely used in residential, commercial, and industrial construction projects due to its strong bonding properties and long lifespan.

Common Applications

- Epoxy flooring systems for factories, warehouses, and hospitals

- Protective epoxy coatings for concrete and steel

- Structural repairs using epoxy adhesives and grouts

The rise of modern infrastructure in cities like Karachi, Lahore, and Islamabad has significantly increased the demand for industrial epoxy resin in Pakistan.

Manufacturing & Industrial Sector

Pakistan’s manufacturing industry relies heavily on epoxy resin for machinery protection, tooling, and industrial coatings. Epoxy-based solutions help improve operational efficiency and equipment durability.

Industrial Uses

- Anti-corrosion coatings for machinery

- Electrical insulation components

- Mold-making and industrial laminates

The consistent performance of epoxy under harsh environments makes it a preferred choice for epoxy resin applications in Pakistan’s industrial sector.

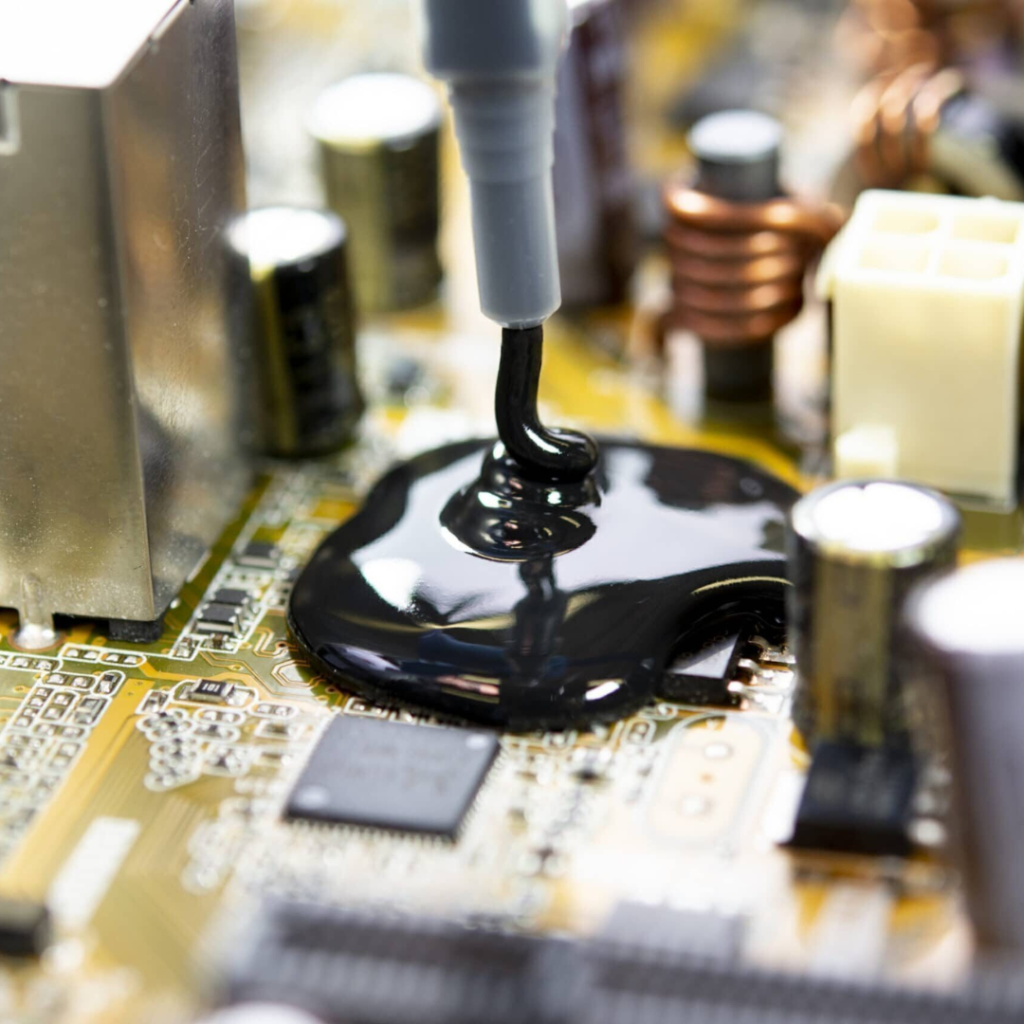

Electrical & Electronics Industry

The electrical and electronics industry is another major contributor to epoxy resin uses in Pakistan. Epoxy resin provides excellent insulation, moisture resistance, and thermal stability.

Key Applications

- Encapsulation of transformers and circuit boards

- Electrical potting compounds

- Insulating coatings for high-voltage equipment

These properties help protect sensitive components from environmental damage and electrical failure.

Automotive & Transportation Industry

Epoxy resin plays an essential role in Pakistan’s automotive and transport-related industries. From vehicle manufacturing to maintenance, epoxy-based materials ensure strength and longevity.

Automotive Applications

- Vehicle body fillers and adhesives

- Protective coatings for chassis and parts

- Composite components for lightweight structures

The growing automobile market has expanded epoxy resin demand in Pakistan across both manufacturing and repair segments.

Marine & Water-Related Projects

Epoxy resin is highly valued in marine environments due to its water resistance and strong adhesion. In Pakistan, it is used for boats, water tanks, and infrastructure exposed to moisture.

Marine Uses

- Boat repairs and fiberglass lamination

- Waterproof epoxy coatings

- Protective layers for water reservoirs

These applications demonstrate the versatility of epoxy resin in Pakistan’s coastal and water management sectors.

Furniture & Woodworking Industry

The furniture and interior design industry has adopted epoxy resin for both functional and aesthetic purposes. Epoxy resin enhances durability while allowing creative designs.

Popular Uses

- Epoxy resin tables and countertops

- Wood bonding and surface sealing

- Decorative finishes

Artisans and manufacturers increasingly rely on epoxy resin uses in Pakistan to create premium furniture products.

Art, Craft & Decorative Industry

Art resin has gained popularity among local artists and small businesses. This creative sector uses epoxy resin for visually appealing, durable artworks.

Creative Applications

- Resin art and wall panels

- Jewelry and craft items

- Customized décor pieces

The growing trend of handmade products has increased awareness of epoxy resin types in Pakistan, especially art-grade resins.

Oil, Gas & Chemical Industry

Epoxy resin is widely used in Pakistan’s oil, gas, and chemical industries due to its resistance to chemicals and extreme conditions.

Industry Uses

- Pipeline coatings

- Chemical-resistant flooring

- Tank linings

These demanding environments rely on high-performance epoxy resin applications in Pakistan for safety and longevity.

Healthcare & Pharmaceutical Industry

Hospitals and pharmaceutical facilities require hygienic, seamless, and easy-to-clean surfaces. Epoxy resin meets these requirements effectively.

Healthcare Applications

- Sterile epoxy flooring

- Wall coatings in laboratories

- Cleanroom environments

This sector continues to expand epoxy resin uses in Pakistan due to strict hygiene standards.

Why Epoxy Resin Is Widely Used in Pakistan

Several factors contribute to the growing adoption of epoxy resin across industries:

- Long service life

- Excellent chemical and moisture resistance

- Strong bonding capability

- Cost-effective over time

These benefits make epoxy resin a reliable solution for diverse industrial and commercial needs.

Conclusion

From construction and manufacturing to art and healthcare, epoxy resin has become an essential material across multiple sectors. The expanding range of epoxy resin uses in Pakistan reflects the country’s industrial growth and evolving market needs. Choosing the right epoxy resin type ensures durability, performance, and long-term value for any application.

FAQ’S

Epoxy resin is widely used in Pakistan across construction, industrial flooring, electrical insulation, automotive components, furniture manufacturing, and protective coatings due to its strength and durability.

The construction, manufacturing, electrical, automotive, marine, and furniture industries are the top sectors using epoxy resin in Pakistan for bonding, coating, and structural applications.

Epoxy resin offers excellent adhesion, chemical resistance, mechanical strength, and long service life, making it ideal for demanding industrial environments.

Yes, epoxy resin is used by small workshops as well as large industrial facilities because it is available in different grades and can be customized for various applications.