As epoxy resin demand grows across construction, flooring, manufacturing, and decorative industries, more buyers are looking to buy epoxy resin Pakistan for a wide range of applications. However, many buyers—especially first-time or price-focused purchasers—end up making costly mistakes that affect quality, performance, and project timelines.

This blog highlights the most common mistakes people make when buying epoxy resin in Pakistan and explains how to avoid them for better results and long-term value.

Choosing Price Over Quality

One of the biggest mistakes buyers make is selecting epoxy resin solely based on the lowest price. While cost is an important factor, extremely cheap epoxy resin often indicates compromised formulation or inconsistent quality.

Low-quality resin can result in:

- Poor adhesion

- Uneven curing

- Reduced durability

- Higher repair and replacement costs

When planning to buy epoxy resin Pakistan, quality consistency should always be prioritized over short-term savings.

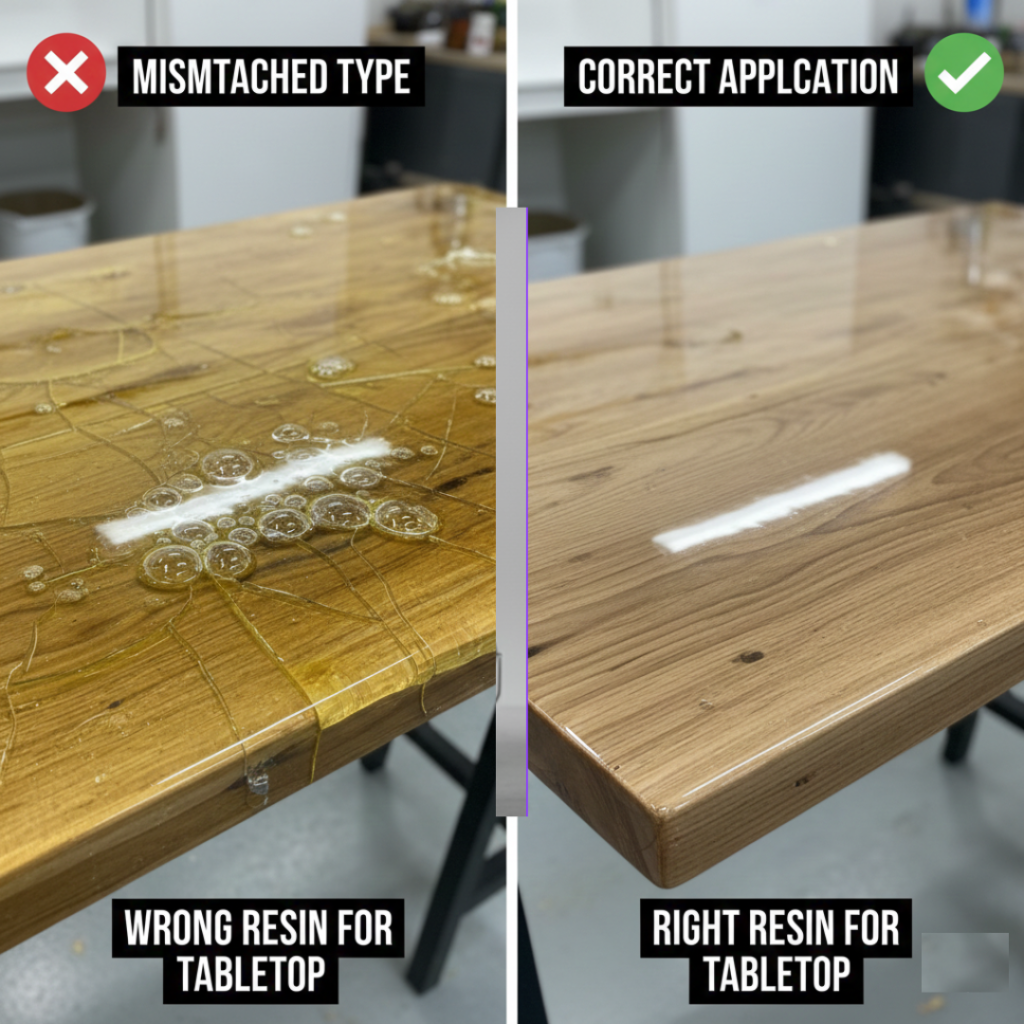

Not Matching Epoxy Resin Type to Application

Epoxy resin is not a one-size-fits-all material. Different formulations are designed for different uses, such as industrial flooring, coatings, electrical insulation, or decorative applications.

Using the wrong type may cause:

- Premature failure

- Surface defects

- Weak bonding

- Unsuitable curing behavior

Buyers should clearly understand their application requirements before making a purchase.

Buying from Traders Without Manufacturing Background

Many buyers unknowingly purchase epoxy resin from traders or resellers who have limited knowledge of production quality or formulation standards. These sellers often source material from multiple manufacturers, leading to inconsistent batches.

This can result in:

- Variation in resin performance

- Lack of technical support

- No accountability for quality issues

Working directly with established epoxy resin manufacturers in Pakistan reduces these risks significantly.

Ignoring Quality Control and Testing Information

Another common mistake is not asking about quality control procedures. Reliable epoxy resin suppliers follow structured testing to ensure consistent viscosity, curing time, and performance.

Failing to verify quality standards may lead to:

- Unexpected curing problems

- Weak surface finishes

- Chemical resistance failures

Always request product specifications or technical guidance before purchasing.

Overlooking Shelf Life and Storage Conditions

Many buyers focus on price and quantity while ignoring epoxy resin shelf life and storage requirements. Poor storage or expired resin can behave unpredictably, even if the product was originally high quality.

Issues caused by improper storage include:

- Thickened resin

- Inconsistent curing

- Reduced bonding strength

Checking manufacturing dates and understanding storage guidelines is essential when buying epoxy resin in bulk.

Not Considering Local Climate Conditions

Pakistan’s climate varies significantly across regions, affecting epoxy resin performance. Temperature and humidity play a major role in curing behavior and application results.

Ignoring environmental conditions can lead to:

- Surface imperfections

- Slow or uneven curing

- Reduced durability

Local manufacturers understand these conditions better and can recommend suitable formulations.

Failing to Plan for Long-Term Supply

For ongoing projects or factory use, buying epoxy resin without supply planning is a common mistake. Switching between suppliers frequently increases the risk of batch inconsistency.

Long-term planning helps ensure:

- Uniform results across project phases

- Stable pricing

- Reliable material availability

Establishing a long-term relationship with a trusted supplier or manufacturer provides consistency and peace of mind.

Not Asking for Technical Support

Epoxy resin application often requires guidance on mixing ratios, curing times, and environmental suitability. Buyers who do not seek technical advice may face avoidable application errors.

Reliable suppliers and manufacturers offer:

- Application guidance

- Product selection support

- Troubleshooting assistance

This support can prevent costly mistakes during application.

Final Thoughts

Buying epoxy resin is not just a purchasing decision—it’s a quality and performance commitment. Avoiding these common mistakes helps ensure successful application, longer service life, and better overall project outcomes.

When planning to buy epoxy resin Pakistan, buyers should focus on quality, correct application, reliable sourcing, and long-term value rather than short-term price advantages.

FAQ’S

Before purchasing, check the resin type, quality standards, manufacturing date, shelf life, and whether it suits your specific application such as flooring, coating, or industrial use.

Buying directly from a manufacturer is usually more reliable, as it ensures consistent quality, technical support, and better pricing compared to traders or resellers.

Avoid choosing resin based only on price. Always ask for product specifications, quality control details, and application guidance to ensure consistent performance.

Yes, temperature and humidity can impact curing and finish quality. Selecting epoxy resin suitable for local conditions helps achieve better and longer-lasting results.